1.7 INTEGRATED

MANAGEMENT SYSTEM – MARINE MAINTENANCE

By Aleksandar

Pudar

Technical Superintendent

and Planned Maintenance Supervisor Reederei Nord BV

Co-founder of "Out of Box

Maritime Thinker Blog" and Founder of Narenta Gestio Consilium Group

Is

safety given the same commitment as performance quality? Are the crew

accountable for their

safety?

Is safety excellence embedded in the company? What is just culture?

1.7.1 SAFETY PERFORMANCE CULTURE

Safety

performance culture is critical in the marine industry, as it is a high-risk

industry with the potential for catastrophic incidents that can result in loss

of life, environmental damage, and financial losses.

The

following steps should be taken to establish a strong safety performance

culture in the marine industry, both on board and on shore :

·

Establish strong

safety leadership: The organisation's leadership should set

an example of safety leadership by emphasising the importance of safety and

ensuring that it is a top priority.

·

Develop and

implement a comprehensive safety management system: The safety management system should include policies, procedures, and

guidelines for identifying and mitigating risks, as well as a reporting and

investigation process for incidents/accidents and near-misses.

·

Provide adequate

training and resources: All employees

should be adequately trained in safety procedures and given the necessary

resources to perform their jobs safely; this includes training on emergency

response, personal protective equipment, and equipment/machinery operation.

·

Encourage open

communication and reporting: Encourage employees

to report safety concerns and near-miss incidents without fear of retribution;

this can help identify potential risks and hazards before they become major

incidents.

·

Conduct regular

safety audits and assessments: Regular safety

audits and assessments should be conducted to identify potential hazards and

areas for improvement.

·

Foster a culture of

continuous improvement: Encourage a culture

of continuous improvement by implementing corrective actions to address

identified safety issues and incorporating lessons learned from incidents and

near-misses.

By

establishing a solid safety performance culture both on board and onshore,

organisations can ensure the safety of their employees, protect the

environment, and maintain their reputation and financial stability.

1.7.2 JUST

CULTURE

Just

culture is a term used to describe a work environment in which individuals are

not punished for their mistakes or errors but rather for their reckless or

intentional behaviour. In the marine industry, a just culture can help promote

safety by encouraging open reporting of incidents and near-misses without fear

of retribution while holding individuals accountable for their actions.

The

following steps should be taken to establish a just culture in the marine

industry :

·

Develop clear

policies and procedures: Develop clear

policies and procedures that outline the expectations for reporting incidents

and near-misses and the consequences for reckless or intentional behaviour.

·

Train employees on

just culture: Train employees on the principles of just

culture and the importance of reporting incidents and near-misses to improve

safety.

·

Implement a fair

and consistent reporting and investigation process: Implement a reporting and investigation process that is fair and

consistent and that takes into account the complexity of the situation and the

actions of the individuals involved.

·

Encourage open

communication: Encourage open communication among

employees and between employees and management to facilitate reporting

incidents and near-misses.

·

Support individuals

involved in incidents: Provide support to

individuals involved in incidents, including access to counselling or other

resources to help them cope with the emotional impact of the incident.

·

Continuously review

and improve the system: Continuously review

and improve the system to ensure that it is effective in promoting safety and

consistent with the principles of just culture.

By

establishing a just culture, the owner and vessel operator can create a work

environment that promotes safety while still holding individuals accountable

for their actions; this can help reduce incidents and near-misses and improve

the safety and well-being of employees and the environment.

1.7.3

MANAGEMENT SYSTEMS - MARITIME INDUSTRY

International Safety Management (ISM) Code

IMO

International Standard for the Safe Management and Operation of Ships and

Pollution Prevention as part of SOLAS Convention - Revised ISM Code Effective

January 1, 2015

The ISM

Code is a global standard for the safe operation of ships and pollution

prevention, established by the International Maritime Organization (IMO) in

1993. It came into force in 1998 and is part of the SOLAS (Safety of Life at

Sea) Chapter IX. The Code aims to foster a safety culture in the shipping

industry and improve compliance with international conventions. The ISM Code

applies to all ships engaged in international voyages of 500 gross tonnages and

upwards, including passenger and cargo ships. The company that owns or operates

the ship is responsible for implementing the Code, which requires developing

and implementing a Safety Management System (SMS).

The ISM

Code contains two parts: Part A outlines the mandatory requirements and

guidance for implementing a safety management system, while Part B provides

certification and verification requirements. Part A covers objectives,

application and functional requirements, safety and environmental protection

policy, company responsibilities and authority, designated person roles and

qualifications, master's responsibilities and authority, shipboard operations,

emergency preparedness, reporting and analysis of non-conformities, accidents

and hazardous occurrences, maintenance of the ship, and ISM documentation,

company verification, review and evaluation. Part B covers certification and

periodical verification, interim certification, verification, and forms of certificates.

The ISM

Code uses several essential terms, such as Safety Management System (SMS),

Designated Person (DP), Document of Compliance (DOC), Safety Management

Certificate (SMC), objective evidence, observation, non-conformity, major

non-conformity, anniversary date, and convention. In addition, the ISM Code

requires ships to maintain a Safety Management Manual readily available on

board for reference. The Code is periodically amended, with the latest version

coming into force on January 1, 2015.

ISO9001:2015

ISO

9001:2015 is a globally recognised standard for quality management systems that

can be implemented by any organisation, including those in the marine industry.

The standard specifies the requirements for a quality management system, which

is a systematic approach to managing processes and procedures that ensure

products and services consistently meet customer and regulatory requirements.

In the

marine industry, ISO 9001:2015 can be used to establish a quality management

system that addresses various aspects of the industry, such as:

·

Safety: The standard requires the owner and vessel operator to identify and

assess risks associated with their activities and take steps to mitigate

them; this could involve implementing

safety procedures and protocols to prevent accidents and spills in the marine

industry.

·

Environmental

Management: ISO 9001:2015 requires organisations to

consider the environmental impact of their activities and implement measures to

minimise their impact. In the marine industry, this could involve implementing

waste management and pollution prevention procedures.

·

Compliance: The standard requires organisations to comply with all relevant legal

and regulatory requirements; this could involve complying with the marine industry's

safety, environmental protection, and security regulations.

·

Continuous

Improvement: ISO 9001:2015 requires organisations to

monitor and improve their quality management system continually. In the marine

industry, this could involve conducting regular audits and assessments of

safety and environmental performance and making improvements where necessary.

ISO14001: 2016

ISO

14001:2015 is an internationally recognised environmental management system

(EMS) standard that provides a framework for organisations to manage their

environmental responsibilities effectively. The standard requires organisations

to identify and control their environmental impacts, comply with relevant

regulations, and continually improve their environmental performance.

In the

marine industry, ISO 14001 can be used to manage and mitigate the environmental

impacts of shipping operations, such as oil spills, emissions, waste

management, and the use of natural resources. The standard can help

organisations to identify environmental risks and opportunities, set

environmental objectives and targets, and monitor and measure their

environmental performance.

Adopting

ISO 14001 can also improve the reputation of the oil tanker marine industry and

enhance stakeholder trust by demonstrating a commitment to responsible

environmental management. In addition, the standard can help organisations to

comply with relevant environmental legislation and regulations, reduce their

environmental impact and costs, and enhance their competitiveness in the

market.

Some of

the key requirements of ISO 14001 include the following:

·

Environmental

policy: The organisation must establish, implement,

maintain and communicate an environmental policy that outlines its commitment

to environmental management and compliance with relevant regulations.

·

Environmental

aspects and impacts: The organisation must identify and assess

the environmental aspects and impacts of its activities, products and services

and establish controls to manage and mitigate their impact.

·

Legal and other

requirements: The organisation must identify and comply

with relevant environmental legislation, regulations, and other requirements.

·

Objectives and

targets: The organisation must establish and maintain

measurable environmental objectives and targets consistent with its

environmental policy and the results of its environmental impact assessments.

·

Environmental

management programs: The organisation must establish and

maintain environmental management programs to achieve its environmental

objectives and targets, including controls and procedures for preventing

pollution and reducing environmental impacts.

·

Monitoring and

measurement: The organisation must establish and

maintain procedures to monitor and measure its environmental performance and to

evaluate compliance with relevant environmental legislation and regulations.

·

Management review: The organisation must regularly review and evaluate the effectiveness

of its environmental management system and identify opportunities for continual

improvement.

Overall,

ISO 14001 can be a valuable tool for the oil tanker marine industry to manage

and mitigate its environmental impacts, enhance stakeholder trust, and improve

its competitiveness in the market.

1.7.3.1 INTEGRATED

MANAGEMENT SYSTEM

An

Integrated Management System (IMS) is a unified system that combines multiple

management systems, including the International Safety Management Code (ISM),

ISO 9001:2015, and ISO 14001:2015. The owner and vessel operator can streamline

operations and improve overall performance by integrating these systems.

The IMS

combines the safety management objectives of ISM, quality management objectives

of ISO 9001, and environmental management objectives of ISO 14001 into a single

system; this allows the industry to manage its operations more efficiently and

effectively, leading to improved safety, quality, and environmental

performance.

The IMS

provides a comprehensive framework for managing all aspects of the marine

industry's operations, from crew training and safety procedures to

environmental impact assessments and waste management. The system is designed

to help organisations identify and manage risks and opportunities, set and

achieve goals and objectives, and continually improve their performance

Implementing

an IMS in the marine industry can bring numerous benefits, including improved

safety, increased efficiency, reduced costs, enhanced reputation, and greater

compliance with international standards and regulations. The system can also

help organisations to manage their environmental impact better, reduce their

carbon footprint, and contribute to sustainable development.

Reliability

engineering ensures that systems, equipment, and machinery operate without any

failures or downtime. An Integrated Management System (IMS) can improve the

reliability of vessels by implementing proactive measures to prevent failures,

improve maintenance practices, and monitor environmental risks.

Combining

ISM, ISO 9001, and ISO 14001 into a single management system helps establish a

comprehensive approach to managing safety, quality, and environmental risks;

this approach eliminates redundancies and inconsistencies when managing these

aspects independently.

Implementing

an IMS can promote a strong safety culture, improve compliance with regulatory

requirements, and reduce the likelihood of environmental incidents; this, in

turn, reduces downtime and maintenance costs while enhancing the overall

reliability of equipment and systems used in tanker operations.

An IMS

can also promote more efficient use of resources, reduce waste, and increase

overall efficiency, leading to cost savings and increased profitability. By

adopting a comprehensive approach to managing safety, quality, and

environmental risks, the tanker industry can improve reliability, reduce

downtime, and enhance overall efficiency, contributing to increased

profitability.

"PLAN-DO-CHECK-ACT"

Plan-Do-Check-Act

(PDCA) is a widely-used management model that can be applied to engineering

maintenance reliability. The PDCA model consists of four steps:

·

Plan: This step involves identifying the problem or issue, setting goals and

objectives, and developing a plan of action. In engineering maintenance

reliability, this could involve identifying potential equipment failures,

setting goals for reducing downtime and developing a maintenance plan.

·

Do: This step involves implementing the action plan, monitoring progress,

and collecting data. For example, engineering maintenance reliability could

involve conducting routine maintenance activities, collecting data on equipment

performance, and monitoring for any signs of failure.

·

Check: This step involves analysing the data collected during the

"Do" step to determine if the goals and objectives have been met. For

example, in the context of engineering maintenance reliability, this could

involve analysing data on equipment performance to identify potential problems,

evaluating the effectiveness of maintenance activities, and comparing actual

downtime to target goals.

·

Act: This step involves taking action based on the results of the

"Check" step; this could involve adjusting the maintenance plan,

changing procedures, or implementing new equipment. In engineering maintenance

reliability, this could involve adjusting the maintenance schedule, modifying

procedures based on lessons learned, or investing in new equipment to improve

reliability.

The

PDCA model encourages a continuous improvement mindset, allowing organisations

to identify areas for improvement and make changes to improve equipment

reliability over time.

https://committee.iso.org/sites/tc207sc1/home/projects/published/iso-14001---environmental-manage/plan-do-check-act-model.html

1.7.4 ACCIDENT/INCIDENT PREVENTION

Accident/incident

prevention is an important aspect of marine engineering reliability. It

involves identifying potential hazards and implementing measures to eliminate

or reduce the likelihood of accidents or incidents occurring.

To

prevent accidents or incidents, marine engineers can implement several

measures, such as:

·

Conducting regular maintenance checks and

inspections to identify potential issues before they become critical.

·

Providing adequate training to crew

members and employees on safety procedures and emergency response protocols.

·

Ensuring all equipment and systems are in

good working condition and operated according to manufacturer guidelines.

·

Conducting regular risk assessments to

identify potential hazards and implementing measures to mitigate the identified

risks.

·

Implementing an Integrated Management

System (IMS) to ensure that safety and environmental risks are managed

effectively.

1.7.5 RISK MANAGEMENT

"Risk is the possibility of an event that will impact achieving

objectives. Risk is measured in terms of likelihood and impact."

Risk

management is an essential aspect of maintaining reliability in the marine

industry. Risk management involves identifying potential risks, assessing their

impact, and implementing measures to mitigate or eliminate them. By adopting a

proactive approach to risk management, the vessel owner /operator can prevent

incidents and accidents, reduce the risk of downtime, and enhance the overall

reliability of the equipment and systems used in tanker operations.

Risk

management also helps to ensure compliance with regulatory requirements and

industry standards. By implementing an IMS that integrates ISM, ISO 9001, and

ISO 14001, the vessel owner/operator can establish a framework for identifying

and managing risks consistently and systematically; this approach helps

eliminate redundancies and inconsistencies when independently managing safety,

quality, and environmental risks.

Risk

management is critical for ensuring marine engineering reliability in the oil

tanker industry. Here are some steps that can be taken for effective risk

management:

·

Identify and assess

risks: The first step is to identify and assess risks

associated with the equipment, systems, and operations of the tanker; this can

involve conducting a risk assessment that considers potential hazards, the

likelihood of occurrence, and the potential consequences of each risk.

·

Develop risk

management strategies: Once the risks have been identified and

assessed, develop strategies to manage them; this can include implementing

measures to reduce the likelihood of occurrence or the severity of

consequences, such as engineering or administrative controls.

·

Implement risk

management strategies: Put the risk management strategies into

action; this can involve implementing new procedures, training personnel, or

modifying equipment or systems.

·

Monitor and review: Regularly monitor and review the effectiveness of the risk management

strategies; this can involve reviewing incident reports, conducting audits, and

evaluating the success of risk mitigation measures.

·

Continual

improvement: Continuously improve the risk management

strategies to ensure that they remain practical and up-to-date; this can

involve conducting ongoing risk assessments, identifying new risks, and

implementing new strategies to manage them.

1.7.5.1 RISK

ASSESSMENT

In

marine engineering reliability, a risk assessment is crucial to identifying

potential hazards and evaluating the likelihood of those hazards occurring in

order to prepare for and mitigate risks. The risk assessment process in marine

engineering reliability includes the following steps:

·

Identify the

hazards: This step involves determining the hazards the

vessel and company face, such as equipment failure, human error, natural

disasters, and environmental hazards. The assessment should also consider

non-routine activities such as repairs and maintenance.

·

Determine who might

be harmed and how: For each hazard identified, the

assessment should consider who will be harmed should the hazard take place:

this includes crew members, passengers, visitors, and the marine environment.

·

Evaluate the risks

and take precautions: The assessment should consider how

likely it is that the hazard will occur and how severe the consequences will be

if it does occur; this evaluation will help determine which hazards should be

prioritised and where risk reduction measures should be implemented.

Precautions may include safety training, regular maintenance and inspections,

and emergency response plans.

·

Record findings: The assessment should be documented, including the hazards

identified, the people and environment they affect, and how the risks will be

mitigated; this documentation should show that the organisation conducted a

proper check of their workspace, determined who would be affected, controlled

and dealt with obvious hazards, initiated precautions to keep risks low, and

kept staff involved in the process.

·

Review and update

the assessment: The assessment should be reviewed and

updated periodically as new equipment, processes, and people are introduced.

Continual review and update will ensure the organisation is prepared to handle

any new risks.

The

marine engineering reliability team can identify potential hazards, evaluate

their risks, and implement measures to reduce the likelihood and severity of

harm; this helps ensure the safety of crew members, passengers, visitors, and

the marine environment and helps the industry comply with legal requirements

and regulations.

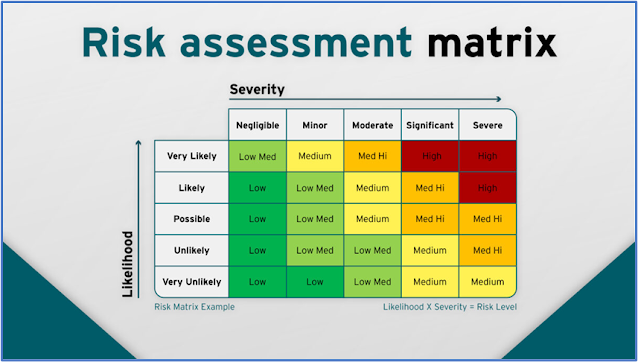

1.7.5.2 RISK MATRIX

Risk

assessment matrices are a popular tool to visualise risk. The most common

matrix is a chart or table that intersects the likelihood versus severity. An

understanding of the risk level can be derived depending on where the

intersection occurs on the axes.

Risk Assesmet Matrix (Riskpal,2023)

The use

of risk categorisation can aid in understanding the level of risk associated

with different activities and how they align with the organisation's risk

appetite. While high-risk activities may yield significant rewards, the

consequences of something going wrong can be too severe for the organisation to

bear.

The

categorisation of risks provides a visual tool for businesses to analyse and

prioritise risks that require urgent mitigation and those that can be managed.

It allows for the systematic assessment of the potential exposure derived from

the risks involved and offers a chance to evaluate if the risks are

proportionate to the potential rewards of the endeavour.

However,

using matrices in risk assessment can be controversial as the assessment is

subject to the assessor's view, making it subjective. There is also a risk of

presenting risk-level judgements as facts.

Moreover,

risk matrices only represent a snapshot of the threat landscape at a specific

time. Therefore, conducting dynamic risk assessments throughout a project's

lifecycle is crucial to maintaining accuracy and preventing overlooked risks.

"The continuous process of identifying hazards, assessing risk,

taking action to eliminate or reduce risk, and monitoring and reviewing the

rapidly changing circumstances of an operational incident is known as a dynamic

risk assessment." HASpod (2022)

1.7.6 EFFECTIVE MEETINGS FOR CONTINUOUS IMPROVEMENT

·

Purpose: The purpose of holding effective meetings for continuous improvement

in marine engineering reliability is to bring together relevant stakeholders to

identify and address safety, reliability, and efficiency issues in marine

engineering operations; this includes identifying areas where improvements can

be made, discussing potential solutions, and establishing action plans to

implement those solutions.

·

Outcomes: The outcomes of effective meetings for continuous improvement in

marine engineering reliability are improved safety, reliability, and efficiency

in marine engineering operations; this can be achieved through increased

collaboration and communication between stakeholders, identification and

resolution of issues, implementation of best practices, and ongoing monitoring

and evaluation of progress.

·

Process: It is crucial to have a structured process in place to ensure that

meetings for continuous improvement are effective; this includes the following

steps:

o Define the meeting purpose: The purpose should

be clearly defined and communicated to all relevant stakeholders to ensure

everyone is aligned and prepared.

o Invite the right stakeholders: Invite stakeholders

directly or indirectly impacted by the issues being discussed and those who can

contribute to the discussion or help implement solutions.

o

Set an agenda: Develop a clear and concise agenda that outlines the meeting

objectives, topics, and timeframes. Then, share the agenda with participants to

ensure everyone is prepared and aligned.

o

Facilitate the

meeting: Use effective facilitation techniques to

encourage participation and collaboration among all attendees. Encourage open

dialogue, active listening, and respectful communication.

o

Document and share

outcomes: Record meeting outcomes, including decisions

made, action items identified, and responsibilities assigned. Share these

outcomes with all participants and stakeholders who may be impacted.

o

Follow-up and

evaluate: Follow up on action items and evaluate progress

towards meeting objectives. Use participant feedback to improve future meetings

and ensure continuous improvement in marine engineering reliability.

1.7.6.1 TOOLBOX

MEETING

A

toolbox meeting on board a vessel related to maintenance can be an effective

way to ensure that the crew is fully aware of the importance of maintenance and

the risks associated with poor maintenance practices.

·

Purpose: The purpose of the toolbox meeting is to provide the crew with an

opportunity to discuss maintenance-related issues, including the importance of

regular maintenance, the consequences of poor maintenance practices, and best

practices for maintaining the vessel's equipment.

·

Outcomes: The expected outcomes of the meeting include increased awareness of

the importance of maintenance, improved understanding of the risks associated

with poor maintenance practices, and increased commitment to maintaining the

vessel's equipment to a high standard.

·

Process: The process for the toolbox meeting could involve the following

steps:

o

Choose a suitable time and location for

the meeting, ensuring that all crew members can attend.

o

Identify the key issues that need to be

discussed, such as the importance of regular maintenance, standard maintenance

tasks, and the risks associated with poor maintenance practices.

o

Prepare a presentation or handout that

covers the key issues and provides practical advice and tips for maintaining

the vessel's equipment.

o

Conduct the toolbox meeting, encouraging

active participation and discussion from all crew members.

o

Use real-life examples and case studies

to illustrate the importance of maintenance and the risks associated with poor

maintenance practices.

o

Conclude the meeting by summarising the

key points discussed and reiterating the importance of maintaining the vessel's

equipment to a high standard.

o

Follow up with the crew to ensure the key

messages from the toolbox meeting are implemented and address any questions or

concerns.

1.7.6.2 ACTION ITEM

MATRIX (AIM)

An

action item matrix is a tool used to track and manage tasks that must be

completed to achieve a specific goal or objective. Project management often

uses it to ensure all necessary tasks are identified, assigned, and completed

on time.

The

matrix typically consists of a table with four quadrants:

·

Urgent and vital: tasks that must be completed immediately and are critical to the

project's success.

·

Important but not

urgent: tasks necessary for the project's success but

can be completed later.

·

Urgent but not

essential: tasks that must be completed quickly but do not

significantly impact the project's success.

·

Not urgent and

unimportant: tasks that can be postponed or

eliminated without affecting the project's success.

Each

task is assigned to one of the four quadrants based on urgency and importance;

this allows the project team to prioritise tasks and ensure the most critical

tasks are completed first.

The

action item matrix is typically reviewed regularly, such as in weekly team

meetings, to ensure that all tasks are being completed on time and to adjust

priorities as necessary. By using this tool, teams can improve their

productivity and efficiency by focusing on the most critical tasks and avoiding

unnecessary distractions.

1.7.6.3 EFFECTIVE

SAFETY TASK FORCES

How are

safety task forces created on a tanker vessel? How are task priorities ranked?

The following process can be applied:

·

Start with defining the AIM or goal of

the safety task force.

·

Consider supervisors trained in

Continuous Improvement (CI) techniques to lead the safety task force.

·

Encourage volunteers to join the team so

they can choose tasks they want to work on and can commit to completing them.

·

Implement short-term, 90-day teams with

effective facilitation, leadership, and closure to ensure the successful

completion of tasks.

·

The teams (both on board and onshore)

should not be initiated if the team lacks effective facilitation, leadership,

and closure.

·

Schedule team meetings every two weeks to

ensure regular communication and connection among team members. (between shore

and onboard team). Onboard/onshore should also meet as necessary to address

specific safety issues.

·

Use this process to develop safety accountabilities

for the crew at various levels, such as defining the winch operator's role

during manoeuvring and prioritising tasks accordingly.

References & Bibliography:

1.

A complete guide to the risk

assessment process (2018) Lucidchart Blog. Lucid Software Inc. Available at:

https://www.lucidchart.com/blog/risk-assessment-process (Accessed: March 30,

2023).

2.

HASpod (2022) The dynamic risk

assessment and when to use it, HASpod. HASpod/ Darley PCM Ltd.

Available at:

https://www.haspod.com/blog/paperwork/what-is-dynamic-risk-assessment

(Accessed: March 30, 2023).

3.

Nicholas, J.M. and Steyn, H.

(2021) Project Management for Engineering, Business and Technology.

Abingdon, Oxon: Routledge, Taylor & Francis Group.

4.

Risk

Assessment Matrix (2023) www.riskpal.com/.

RiskPal. Available at:

https://riskpal.com/wp-content/uploads/2022/11/RP_Cover_What-is-a-risk-assessment-matrix-1-1200x675.jpg

(Accessed: March 30, 2023).

Disclaimer:

Out

of Box Maritime Thinker © by Narenta Gestio Consilium Group 2022 and Aleksandar

Pudar assumes no responsibility or liability for any errors or omissions in the

content of this paper. The information in this paper is provided on an "as

is" basis with no guarantees of completeness, accuracy, usefulness, or

timeliness or of the results obtained from using this information. The ideas

and strategies should never be used without first assessing your company's

situation or system or consulting a consultancy professional. The content of

this paper is intended to be used and must be used for informational purposes

only.