AI-Based Predictive Maintenance - Start

The start of AI-based predictive maintenance is data

collection and pre-processing. This involves gathering data from various

sensors placed on the machines or embedded in the machine itself. The data can

include temperature, pressure, vibration, and load. This data is then

pre-processed to remove any outliers or noise and to ensure the data is in a

format suitable for analysis.

One common approach to anomaly detection in rotating

machinery is to use statistical models such as Gaussian Mixture Models or Hidden

Markov Models. These models are trained on historical data collected from the

equipment to establish normal operating conditions. Then, real-time data can be

compared to the model to identify deviations from normal behavior, which can

be flagged as an anomaly.

Another anomaly detection approach is using machine learning

algorithms such as clustering or deep learning. For example, a clustering

algorithm can be used to group similar patterns in the data and then identify

any significantly different patterns. Deep learning algorithms such as

autoencoders or recurrent neural networks can also detect anomalies by learning

patterns in the data and comparing new data to the learned patterns to identify

any deviations.

Once the data is pre-processed, the next step is to perform

feature engineering, which involves selecting and transforming the relevant

variables from the data to help improve the accuracy of the predictive models.

Once anomalies have been detected, it is vital to interpret

the data and determine the root cause of the problem. This information can then

be used to make informed decisions about the maintenance that needs to be

performed, such as replacing a worn part or performing a routine check.

After feature engineering, the next step is to choose a

suitable machine learning algorithm to develop the predictive maintenance

model. This can include algorithms such as random forests, decision trees,

support vector machines, or neural networks. The choice of algorithm will

depend on the complexity of the data and the problem being solved.

Rotating Machinery - Anomaly Detection

Through regular use, the deterioration of a rotating

machine, such as a pump or fan, can produce anomalies, which should be viewed

as a warning of suboptimal conditions rather than a complete shutdown. Sensors

play a critical role in detecting these anomalies, as the sensors and sensor

outputs used in anomaly detection significantly impact their performance.

Therefore, choosing sensors with the appropriate capabilities and features is

essential. However, there is still a risk of error if the data from these

sensors is not accurately transferred to the model. Incorrect data transfer can

result in false-positive alarms, causing a waste of time and effort or even

more severe consequences such as missed alarms and material and moral damage.

Supervised learning is impossible when no labelled data from machines with

historically defective and healthy signals exist. In this situation, a machine

learning model can be trained on a training set consisting only of

"normal" samples. Then, an anomaly alarm can be triggered based on

measuring the distance between the original signal and the predicted signal.

However, we need to define "normal" and

"abnormal" at this stage, which can be challenging. One way to

overcome this challenge is to use unsupervised learning methods such as

clustering or autoencoders. Clustering methods group similar data points

together, and if there is an anomaly in the data, it will be placed in its

cluster, making it easy to identify. Autoencoders are neural networks that can

reconstruct the input data, and any deviation between the input data and the

reconstructed data can indicate an anomaly.

Another technique that can be used in anomaly detection is

time-series analysis, where the behavior of the rotating machine over time is analysed

to detect any deviations from normal behavior. For example, the vibration signal

of a machine can be analysed over time to detect any changes in the frequency

spectrum or any sudden spikes in vibration. These changes can indicate a

potential issue with the machine, and maintenance can be performed to prevent a

complete failure.

Feature Extraction

Rotating equipment operates by generating vibrations and

maintaining these vibrations at acceptable levels for reliable production. To

detect anomalies in these machines, sensors play a crucial role in the

predictive maintenance process. Vibrations measured by accelerometers are the

most basic units for detecting anomalies. Two main features can be extracted

from the acceleration signals collected: time domain features and frequency

domain features.

Metrics such as RMS, Crest, Kurtosis, and Peak can be

obtained from the time domain. In contrast, total harmonic distortion, harmonic

indications, spectral centroid, and sideband energy are extracted from the

frequency domain. It is crucial to transfer these frequency domain features to

the machine learning model to create a reliable model. The frequency content is

a signature of the normal or abnormal state of the machine, and the speed

information should also be included in the model for independent harmonic

analysis. With each frequency amplitude from a 3-axis vibration sensor entered

as a feature, the machine learning model can compare thousands of features in a

multi-dimensional mathematical space, allowing even the most subtle anomalies

to be detected based on the model's resolution.

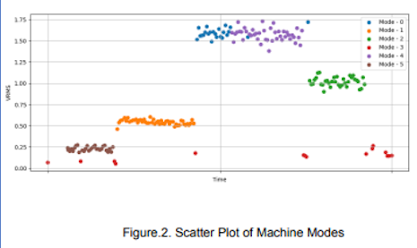

Machine Mode Analysis

Numerous types of machines are utilized in various

industries, each designed to perform different functions. These machines

operate in cycles powered by various factors like fluctuating production speed,

raw materials, and processes. For instance, the speed of a rolling mill may vary

based on the desired material quality, thickness, and production speed. As a

result, the vibration data from the machine also changes with the speed.

In traditional predictive maintenance applications, anomaly

alarms may trigger with every speed change, which is inaccurate. In such cases,

it is crucial to include process parameters like speed, power, etc., in the

model and determine the different machine modes first. For example, during a

test on a roller, vibration data was collected at four different speeds, and

the machine learning model revealed six distinct modes. Four of these modes

operate at different speeds, one is the mode in which the machine is idle, and

the last mode is the mode in which anomalies occur.

The graph shows five groups if the measurements are not

coloured, but the model has six modes because the machine's operating cycle in

one cluster, divided into two groups, is the critical speed. This leads to

mechanical looseness and coupling over time, resulting in a new abnormal mode

(purple measurements in Figure 2). Although the standard deviation of the data

in the cluster is evident compared to other clusters, it is challenging to

distinguish two different modes in that cluster.

Two measurements operating in the same mode can be

differentiated by their spectral information, as shown by the blue and purple

plots. However, it may not be easy to distinguish these two measurements by

looking at their average Vrms values. The reason is that Vrms may not be

sufficient for high-frequency vibrations and may not detect anomalies in some

fault types. Hence, transferring all spectral information to the machine

learning model ensures optimal results in anomaly detection.

Conclusion

AI-based predictive maintenance is crucial in detecting and

preventing failures in rotating machinery. The first step in implementing AI-based

predictive maintenance is data collection and pre-processing, followed by

feature engineering and selecting the appropriate machine learning algorithm to

develop the predictive maintenance model. Vibration signals measured by

accelerometers are the most commonly used sensors in predictive maintenance,

and features such as RMS, Crest, Kurtosis, Peak, total harmonic distortion,

harmonic indications, spectral centroid, and sideband energy can be extracted

from the signals for analysis. Furthermore, time-series analysis and

unsupervised learning methods like clustering and autoencoders can detect

rotating machinery anomalies. Additionally, it is essential to include machine

mode analysis and process parameters in the predictive maintenance model to increase

its accuracy.

References

1.

www.rolls-royce.com. (n.d.). Rolls-Royce opens

first Ship Intelligence Experience Space. [online] Available at:

https://www.rolls-royce.com/media/press-releases/2017/27-11-2017-rr-opens-first-ship-intelligence-experience-space.aspx

[Accessed 13 Feb. 2023].

2.

Medium. (n.d.). Medium. [online] Available at:

https://medium.com/@connect.hashblock/the-ultimate-guide-to-decision-tree-algorithms-2ff42d7cf6c

[Accessed 13 Feb. 2023].

No comments:

Post a Comment